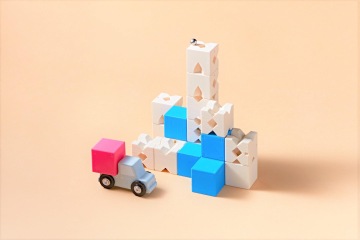

3D printing production technology and internal structure of the KODA cubes

We printed the first prototypes with a grid filling. It was not bad, but from a technical point of view, such a filling has very different mechanical loads in different directions of force. It does not affect the function of the cubes, because in normal use of the cubes, the force acting on the cubes does not come close to the limits of what the material can withstand, but from the designer's point of view, the gyroid type filling we use now, is better. The gyroid filling is more difficult to calculate the print code (but it doesn't matter, the computer can handle it) and is more variable in space and offers a more even capture of forces from all directions of action. In short, the use of a gyroid filling is a more elegant technical solution.

We probably agree that no product is perfect. But it is also true that the product can be more or less close to perfection. I will try to use an example from the world of racing cars to help explain the philosophy of product design that we stand for. Imagine that we want to design, for example, the axle arm of a race car. And let's ask ourselves when this arm will come close to perfection. If we omit other factors such as the material and its correct shapes, we can simply say that the arm will be perfect if it is designed so that further thinning or lightening of the material would already lead to the destruction of the arm under load. In other words, it will work best in a race car if it is not oversized, but also undersized so that it does not crack. Furthermore, of course, the production technology is important, which can greatly affect the properties of the material, its strength, manufacturability of the part in ideal shapes, etc. It is similar with KODA cubes, 3D printing technology is in their case "extracted to the edge" in many ways, geometry , use of the inner space of functional cubes, manufacturability from one piece of material with integrated automatic magnetic system 8M-Tronic®, production using a small amount of energy, material utilization of more than 98%, biodegradability, absolutely harmless material, lifetime warranty, and maybe we would find more other factors that make the construction of KODA magnetic cubes unique.

Prague | 11.2.2021 | Jiri Capek